irongrindingmill

.jpg)

China Iron Grinding Mill Manufacturers and Factory,

Iron Grinding Mill China Manufacturers, Suppliers, Factory Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new Three features of stirred mills that transform the economics of fine grinding are : the high intensity attrition grinding environment the ability to use fine grained media (eg 1 mm) to Fine Grinding as Enabling Technology – The IsaMill

.jpg)

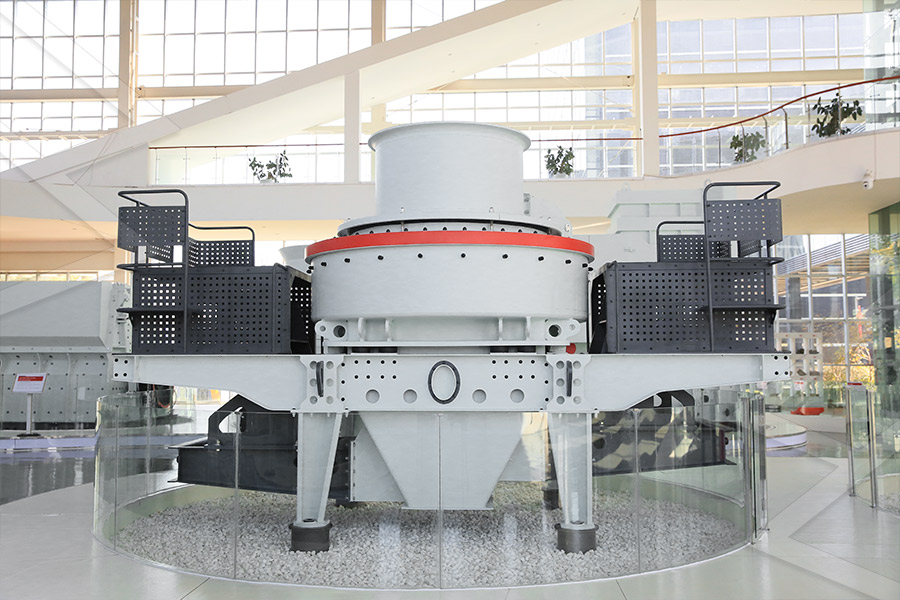

Simple Ore Extraction: Choose A Wholesale ore iron grinding mill

Find the right mine mill from Alibaba Explore our mining equipment to find the ideal wholesale ore iron grinding mill model and mills for any mining challengeAn iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particles Grinding iron ore concentrate by using HPGR and ball mills

.jpg)

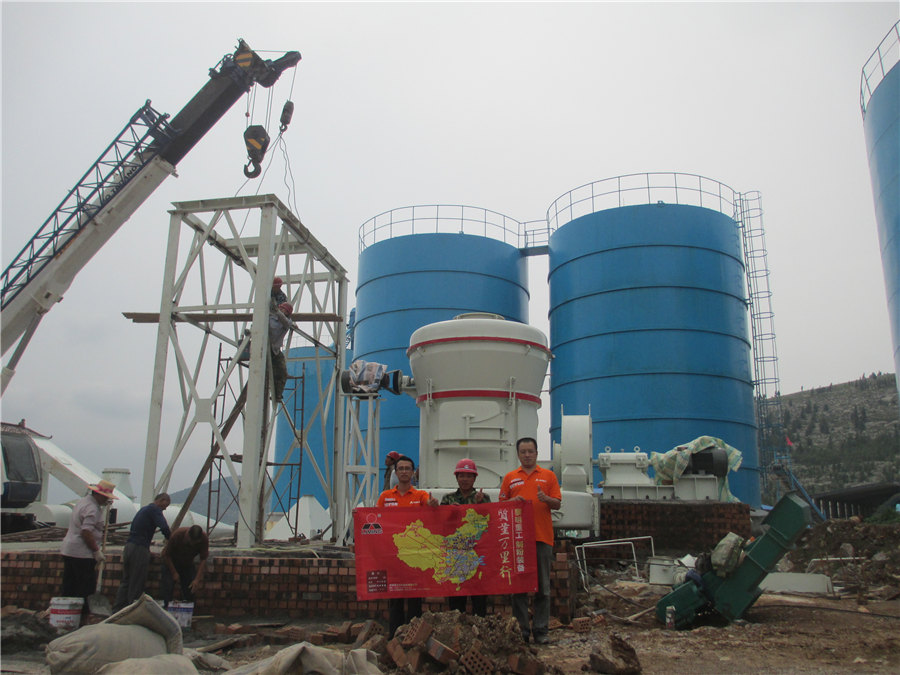

NRRI advances efficient grinding technology on the Iron Range

May 6, 2024 Pilotscale, vertical mill from Switzerland is ‘gamechanger’ for industry decarbonization efforts A crucial step in mineral processing – and in Minnesota’s iron 实现研磨效果的全面组合方案 研磨是矿石获得过程中重要而关键的部分。 通常来说,在整个开采过程中,研磨是颇为耗能的过程。 为了确保业务盈利,需要设计一个有效的磨矿回路。 特别是现在,因全球矿产资源正在减 磨机 ABB

Iron Grind Mill China Trade,Buy China Direct From Iron Grind

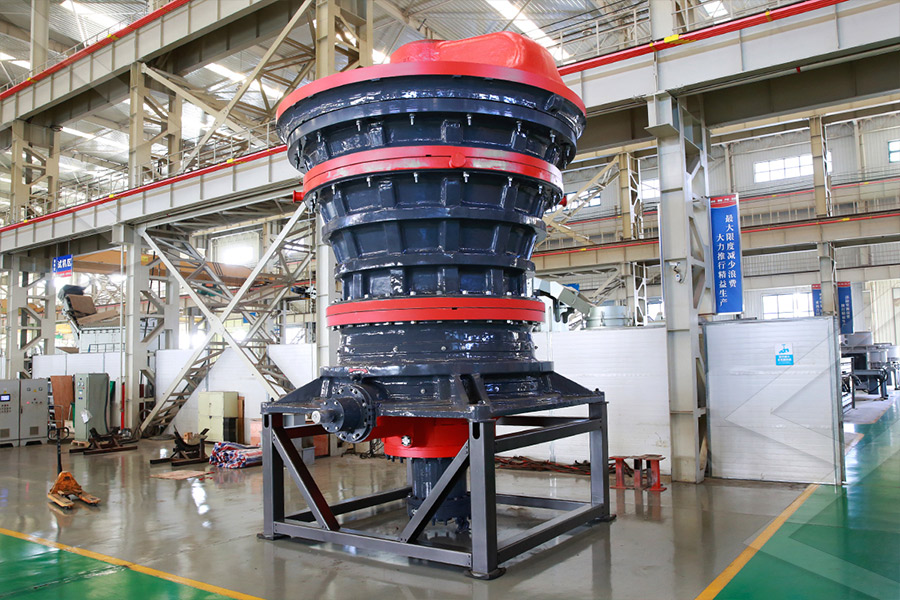

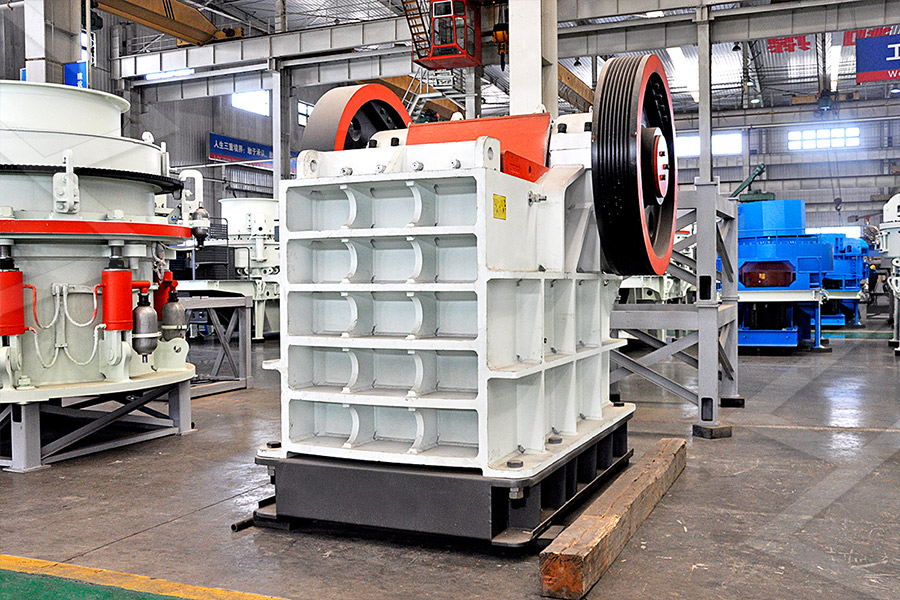

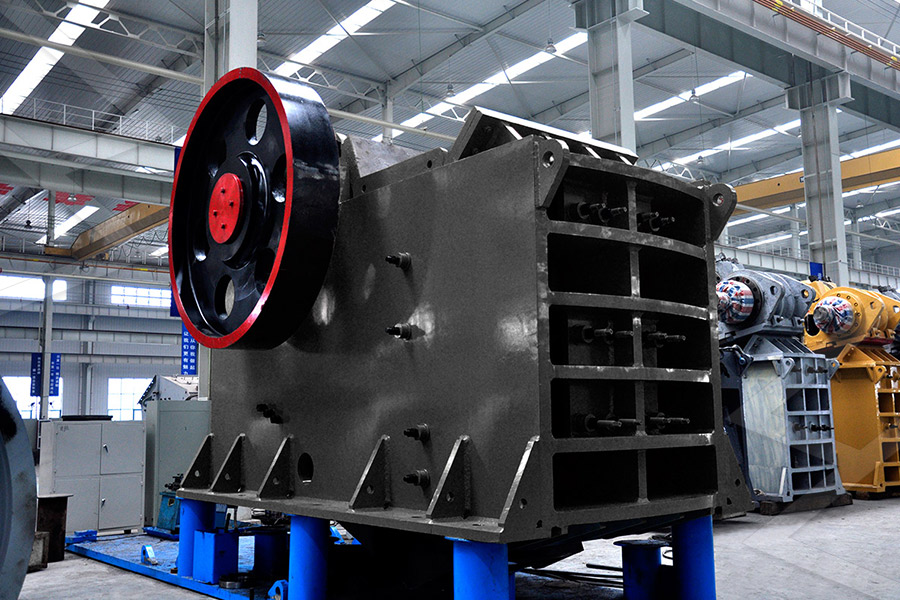

Buy Iron Grind Mill China Direct From Iron Grind Mill Factories at Alibaba Help Global Buyers Source China Easily2012年2月6日 The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are jaw crusher, cone crusher, hammer crusher Iron Ore Crushing and Grinding MachinesCSDN博客

.jpg)

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The size of 30 mm was optimum for raw materials of −045 + 015 mm and −015 mm The optimal ball size distribution was 12 mm (40%), 20 mm (40%), 32 mm (10%), and 40 mm (10%) for dry finegrinding of calcite ore Finer ball loads were unable to break coarser particles nipped in the feed2013年8月1日 A wide range of materials is used to resist wear in comminution processes (Durman, 1988, Moema et al, 2009)The abrasiveness of the material being processed is of prime importance in determining the absolute wear rate of the grinding media, but conflicting characteristics of high hardness for maximum wear resistance and adequate ductility, to Consumption of steel grinding media in mills – A review

.jpg)

Cross Beater Mill cast iron grinding insert

OVERVIEW The fast mill for all tasks With a freely adjustable rotor speed of 2,000 – 4,000 rpm, the FRITSCH Cross Beater Mill PULVERISETTE 16 is the ideal universal mill for fast and gentle precrushing and finegrinding 2014年1月1日 The work demonstrates the application of the population balance model in the optimization of a fullscale ball mil circuit grinding pellet fines with the aim to evaluate the optimal solids (PDF) Population balance model approach to ball mill

.jpg)

(PDF) Morphology and wear of high chromium and

2021年11月1日 Comminution is a very important and resultdetermining step in mineral processing This is because further downstream processes in the beneficiation chain depend entirely on it2015年3月15日 One contribution to minimise the increase is to use more efficient comminution equipment Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are Research of iron ore grinding in a verticalrollermill

.jpg)

Population balance model approach to ball mill

2024年1月2日 3 BALL MILL MODEL The population balance model may be expressed by Equation (1): > @ ¦ i1 1 i b ij m j j i j i S Ht dt d H m t (1) where: S i (t) is the size discretized selection function for IronMills Grinders will Amaze Your Senses Our luxury castiron salt and pepper mills are a treat for all your senses Each mill is carefully cast and finished The comforting heft of the cast iron will remind you of its quality with every use Our remarkable colour selection will certainly match your personal styleIronMills Quality Cast Iron Salt Pepper Mills UK Made

.jpg)

Grinding Mills 911 Metallurgist

3 天之前 The graph below will be helpful in determining percentage of critical speed when internal mill diameter and RPM are known A Grinding Mill is a revolving cylinder loaded to approximately onehalf its volume with steel rods, balls or pebbles Grinding mills reduce particle size by impact, rolling and slidingRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill

.jpg)

Mechanistic modeling and simulation of grinding iron ore

DOI: 101016/JPOWTEC202107030 Corpus ID: ; Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrialscale ball mills @article{Carvalho2021MechanisticMA, title={Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrialscale ball mills}, author={Rodrigo M de 2023年11月1日 1 Introduction Grinding operation is the last preparation stage before beneficiation In this stage, the material undergoes the combined action of impact and grinding, so that the ore particle size is diminished and the qualified materials is provided for succeeding beneficiation operations [1, 2]Generally, the quality of the grinding product is Energy conservation and consumption reduction in

.jpg)

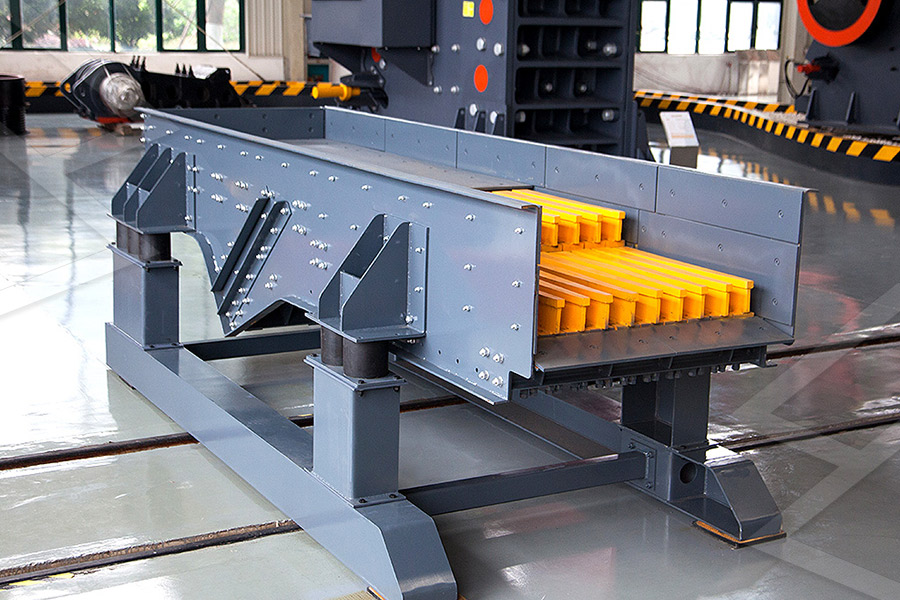

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushing This step prevents overloading the crusher and increases its efficiency2017年2月20日 Type CHRK is designed for primary autogenous grinding, where the large feed opening requires a hydrostatic trunnion shoe bearing Small and batch grinding mills, with a diameter of 700 mm and more, are available These mills are of a special design and described on special request by all Ball Mill ManufacturersGrinding Mill Design Ball Mill Manufacturer 911

.jpg)

Fine Grinding as Enabling Technology – The IsaMill

Stirred Milling Technology Three features of stirred mills that transform the economics of fine grinding are : the high intensity attrition grinding environment the ability to use fine grained media (eg 1 mm) to suit to the fine grained feed the ability to use cheap natural products (local sand, slag, ore) as grinding media2023年5月2日 Find the Ktaxon food mill on Wayfair now 3 StonePlus Made of handsome natural granite with an attractive wooden stand, the StonePlus handcrank food mill effectively grinds coffee, grains, legumes, nuts, seeds, and spices and adds an appealing, rustic touch to any kitchenThe Best Countertop Grain Mills and Flour Grinders in 2023 Foodal

5 Best Manual Grain Mills For Freshly Ground Flour Build a

2024年3月19日 Country Living Grain Mill Corona Corn and Grain Mill WonderMill Jr Hullwrecker 2 Roller I believe every food prepper ought to know how to grind grain into flour Whether it is for being prepared against a future emergency or to begin to brew your brand of beer, a manual grain mill can come in very handy2024年5月6日 A crucial step in mineral processing – and in Minnesota’s iron ore processing – is comminution, a process of crushing and grinding Large rocks must first be crushed and then ground down to tiny particles to expose the valuable or desired minerals so they can be separated from the waste rock The prevalence of lowgrade and complex NRRI advances efficient grinding technology on the Iron Range

(PDF) Redesign of a grinding mill for the minimisation

2009年10月1日 Surface grinding is a manufacturing process which move s a grinding wheel relative to a surface in a plane while a grinding wheel contacts the surface a nd removes a minute amount of material Invested 70 million yuan to acquire Jinan Xing Tiger Paper Making Co, Ltd I, Approved Hightech enterprises Factory Area extend to 80000m² Annual Production Capacity to tons Jinan Huafu Forging joint stock Co,Ltd Founded Selfstudy 80100mm big diameter automotive steel ball productionJinan Huafu Forging JointStock Co, Ltd

.jpg)

Grinding Media Balls Manufacturers in India,

P A Steel Co is a trusted name among the Grinding Media Balls, Grinding Cylpebs Manufacturers in India Established in the year 1997, we P A Steel Co is counted amongst the prominent manufactures of a wide range of 2015年3月15日 The total energy consumption for ore comminution will further increase within the next decades One contribution to minimise the increase is to use more efficient comminution equipment Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principleResearch of iron ore grinding in a verticalrollermill

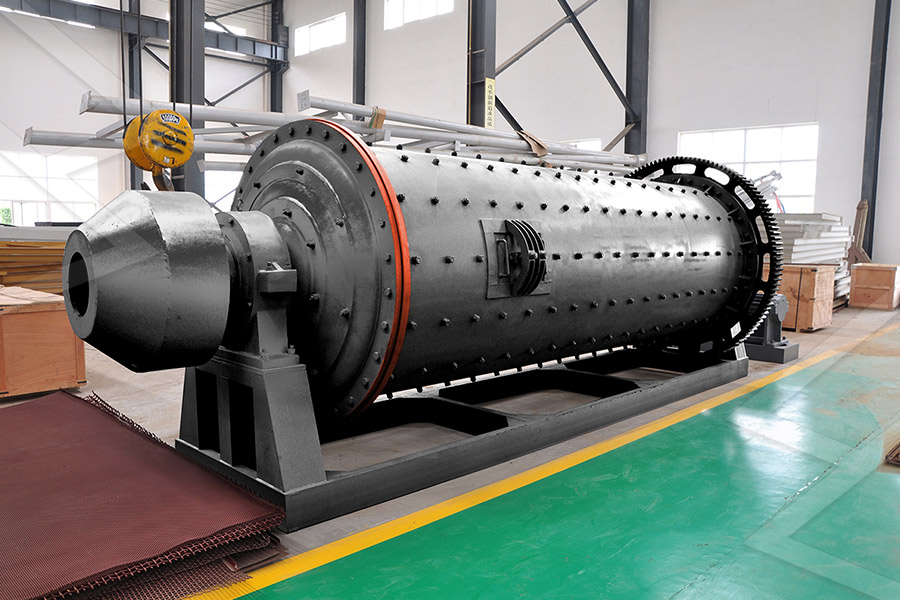

Ball Mill Ball Mills Wet Dry Grinding DOVE

1 天前 DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (03 TPH – 80 TPH) With over 50 years experience in Grinding Mill Machine fabrication, DOVE Ball Mills as 2015年3月15日 DOI: 101016/JMINENG201407021 Corpus ID: ; Research of iron ore grinding in a verticalrollermill @article{Reichert2015ResearchOI, title={Research of iron ore grinding in a verticalrollermill}, author={Mathis Reichert and Carsten Gerold and Andreas Fredriksson and G Adolfsson and Holger Lieberwirth}, journal={Minerals Research of iron ore grinding in a verticalrollermill

.jpg)

Relationship between microstructure, hardness, impact

2004年2月1日 The microstructures of the test balls in both the ascast and heattreated conditions are shown in Fig 1, Fig 2, Fig 3, Fig 4, Fig 5, Fig 6 Fig 1 shows the microstructure of the low alloy steel balls The structure is composed of very fine pearlite barely resolvable even at high magnification2014年10月20日 Fitting the population balance model of batch grinding to data from a 254 cm mill in size reduction of an iron ore resulted in nonnormalizable breakage functio ns and bre akage rate (PDF) Population balance model approach to ball mill optimization

%3C1PGHL[2}HK_]YT.jpg)

Steel Grinding Balls For Sale In Bulk – Kemcore

SAG Mill Grinding Media From $999 Kemcore is your trusted supplier of forged steel grinding balls for your ball mill manufactring process Buy now at factory pricesThe IsaMill™, as shown in Figure 815, is a horizontal stirred mill consisting of a series of 7–8 rotating grinding disks mounted on a cantilevered shaft that is driven through a motor and gearbox The disks operate at tip speeds of 21–23 m/s, resulting in energy intensities of up to 300 kW/m 3The mill is filled with suitable grinding media, and the space between Stirred Mill an overview ScienceDirect Topics

.jpg)

(PDF) Corrosion of Cast Iron Mill Plates in Wet Grinding

2010年7月1日 Abstract Corrosion studies were carried out on two different maize grinding plates Maize was soaked in water for three days and the water decanted and used as electrolyte Mass loss and pH 2021年11月1日 The pilotscale mill consisted of a 416 cm diameter cylindrical steel shell that was fitted with eight 130 mm width and 60 mm height rectangular lifters (Fig 2)The mill was fitted with two exchangeable discharge endplates, allowing for either overflow or grate discharge operation (Fig 2)The dry ore entered the mill through a variable speed Mechanistic modeling and simulation of grinding iron

Investigation on Iron Ore Grinding based on

2020年5月28日 The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore Grinding 2018年8月17日 Rod Mills — these rotating mills use rods for grinding media causing friction and attrition between steel rods and ore particles Rod mills can accept feed up to approximately 50 mm (2 in) and Grinding Mills — Types, Working Principle Applications

(PDF) The effects of iron ore concentrate grinding

PDF On Oct 18, 2020, Seyed Hamzeh Amiri and others published The effects of iron ore concentrate grinding methods (HPGR and Ball mill) on green pellet properties a pilot plant case study Find 2017年11月1日 Wear test equipment Based on the motion law of the steel ball and the liner in the ball mill, the friction test rig for the grinding ball and the liner is designed, which has a fixedball configuration, as shown in Fig 3 The test rig has a rotating ball, which the plate is pushed against to exert a certain normal forceFriction and wear of liner and grinding ball in iron ore ball mill

CFB石灰石脱硫剂制备64.jpg)

Research of iron ore grinding in a verticalrollermill CEEC

2024年4月16日 The Coalition for Energy Efficient Comminution (CEEC) has been established and is supported by a broad range of mining sector companies keen to accelerate awareness, knowledge transfer and, by implication, improve energy and cost outcomes in the substantive area of comminution2017年6月15日 Abstract To understand the friction and wear of working mediums in iron ore ball mills, experiments were conducted using the ball cratering method under dry and wet milling conditions, which Friction and wear of liner and grinding ball in iron ore ball mill

.jpg)

Mining Welcome to AIA Engineering/Vega Industries

We manufacture Grinding Media with chrome content ranging from 3% to 33% in sizes ranging from 12mm to 125mm as required by the application Enhanced profitability of mining companies is assured with Vega High Chrome Grinding Media solutions Marked Ball Test (MBT) tests are conducted to arrive at minimum wear cost of Grinding Media (TCO)2023年10月27日 The size of 30 mm was optimum for raw materials of −045 + 015 mm and −015 mm The optimal ball size distribution was 12 mm (40%), 20 mm (40%), 32 mm (10%), and 40 mm (10%) for dry finegrinding of calcite ore Finer ball loads were unable to break coarser particles nipped in the feedA Review of the Grinding Media in Ball Mills for Mineral

Consumption of steel grinding media in mills – A review

2013年8月1日 A wide range of materials is used to resist wear in comminution processes (Durman, 1988, Moema et al, 2009)The abrasiveness of the material being processed is of prime importance in determining the absolute wear rate of the grinding media, but conflicting characteristics of high hardness for maximum wear resistance and adequate ductility, to OVERVIEW The fast mill for all tasks With a freely adjustable rotor speed of 2,000 – 4,000 rpm, the FRITSCH Cross Beater Mill PULVERISETTE 16 is the ideal universal mill for fast and gentle precrushing and finegrinding Cross Beater Mill cast iron grinding insert

.jpg)

(PDF) Population balance model approach to ball mill

2014年1月1日 The work demonstrates the application of the population balance model in the optimization of a fullscale ball mil circuit grinding pellet fines with the aim to evaluate the optimal solids 2021年11月1日 Alloyed Ductile iron, austenitized at 840 °C for 30 min in a special sealed austempering furnace, was austempered for 30 min in molten salt mixture at 4 trial temperatures of 300 °C, 320 °C (PDF) Morphology and wear of high chromium and

.jpg)

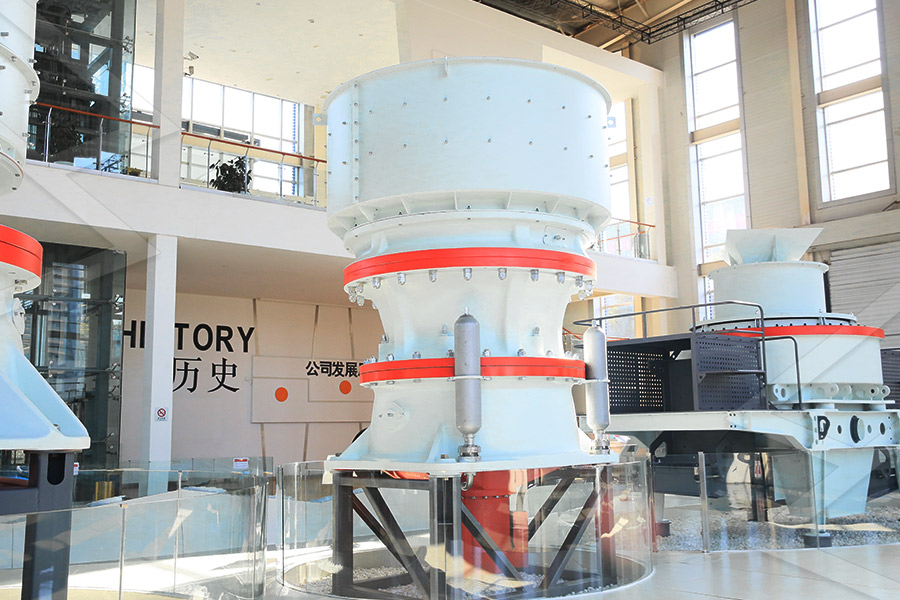

Research of iron ore grinding in a verticalrollermill

2015年3月15日 One contribution to minimise the increase is to use more efficient comminution equipment Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are 2024年1月2日 3 BALL MILL MODEL The population balance model may be expressed by Equation (1): > @ ¦ i1 1 i b ij m j j i j i S Ht dt d H m t (1) where: S i (t) is the size discretized selection function for Population balance model approach to ball mill

.jpg)

IronMills Quality Cast Iron Salt Pepper Mills UK Made

IronMills Grinders will Amaze Your Senses Our luxury castiron salt and pepper mills are a treat for all your senses Each mill is carefully cast and finished The comforting heft of the cast iron will remind you of its quality with every use Our remarkable colour selection will certainly match your personal style3 天之前 The graph below will be helpful in determining percentage of critical speed when internal mill diameter and RPM are known A Grinding Mill is a revolving cylinder loaded to approximately onehalf its volume with steel rods, balls or pebbles Grinding mills reduce particle size by impact, rolling and slidingGrinding Mills 911 Metallurgist